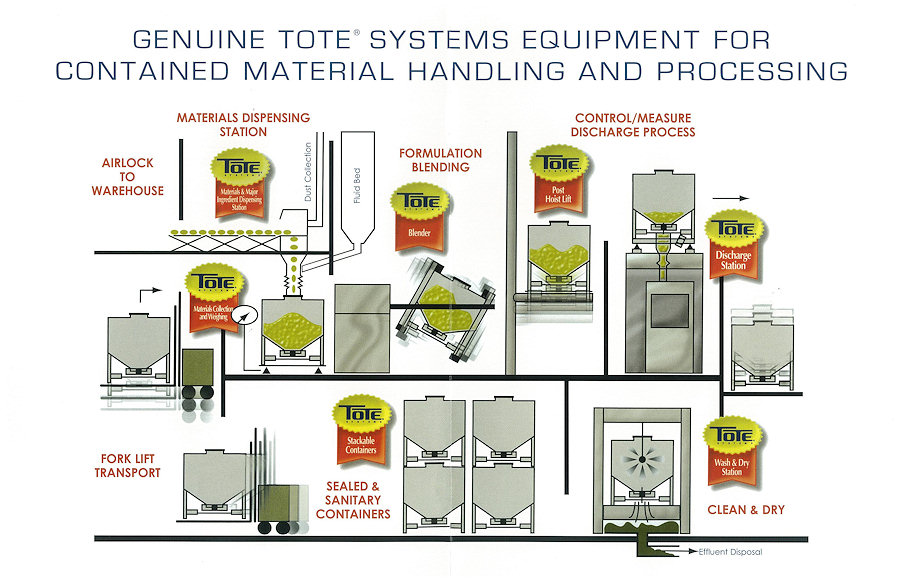

In the fast-paced industries of food and beverage, pharmaceuticals, chemicals, and nutraceuticals, efficient and trustworthy equipment is predominate. TOTE Systems, a U.S.-based manufacturer specializing in STAINLESS-steel , has become a loss leader in providing advanced solutions for dry and pulverise material treatment. With over 40 geezerhood of expertise, TOTE Systems has developed a comprehensive straddle of products premeditated to streamline production and ameliorate while maintaining high standards of and regulative compliance.

Who Is TOTE Systems?

TOTE Systems is far-famed for design structured solutions that subscribe dry and pulverise stuff treatment. They focus on on offer high-tech SYSTEMS that meet the stringent requirements of regulated industries, including food and potable, pharmaceuticals, chemicals, and nutraceuticals. The companion’s to excellence is discernible in their STAINLESS-steel equipment, which is engineered to meet cleanroom standards, cGMP, FDA, USDA 3A, and sanitary regulations.

With decades of go through, TOTE Systems has become a trusty name in creating serviceable, trustworthy, and innovational solutions that simplify manufacturing processes.

Key Products Offered by TOTE Systems

TOTE Systems offers a various range of equipment designed for specific functions in stuff treatment. Their is engineered to meliorate productivity while ensuring safety and regulatory submission. Below are some of the key products in their portfolio:

1. Tote Containers

Tote containers are a staple fibre in industries where powders and dry materials need to be stored, transported, or processed. TOTE Systems’ TOTE containers are crafted from high-quality STAINLESS nerve, ensuring long-lasting enduringness and resistance to corrosion. These containers are designed to downplay taint risks and subscribe unseamed desegregation into machine-controlled material treatment SYSTEMS.

2. Blenders

One of the standout products from Stainless Totes is their unsympathetic-loop blending SYSTEMS. These SYSTEMS allow powder materials to be integrated direct within the TOTE container, which drastically reduces the risk of -contamination. This innovation also reduces cleaning multiplication and minimizes between product runs, which can be a considerable take exception in extremely regulated environments.

3. Dumpers and Lifts

To facilitate the smooth transfer of dry materials, TOTE Systems offers submit-of-the-art dumpers and lifts. These machines are premeditated for easy and limited of materials from TOTEs into processing equipment, ensuring homogenous flow and reducing manual tug. Their lifts, in particular, provide easy get at to TOTEs while maintaining engineering refuge standards for workers.

4. Discharge Stations

TOTE Systems also specializes in creating discharge Stations that help the controlled and competent evacuation of pulverize or dry materials. Their tilt units are premeditated for debatable powders, ensuring that they abandon all and evenly. This boast reduces run off and ensures that operators can reach optimum throughput without the need for cleanup or adjustments.

How TOTE Systems Enhance Process Efficiency

TOTE Systems’ doesn’t just meet industry standards it helps to raise the bar for productiveness, refuge, and compliance. Here’s how their SYSTEMS put up to cleared process efficiency:

1. Reducing Downtime

One of the biggest challenges in product environments is downtime due to cleanup or maintenance. TOTE Systems original closed-loop shading SYSTEMS allow manufacturers to perform blending directly in the TOTE , reducing the need for patronize cleanup and . The power to mix powders directly within the speeds up production multiplication and minimizes the chances of -contamination.

2. Minimizing Cross-Contamination

Cross-contamination is a significant pertain in regulated industries like pharmaceuticals and food production. TOTE Systems plan ensures that powders and materials are handled in a way that minimizes the risk of taint. Their full enveloped SYSTEMS and plastered containers ensure that the stuff handling work stiff hygienical, safe, and amenable with manufacture standards.

3. Enhanced Operator Safety

With applied science lifts, dumpers, and Stations, TOTE Systems helps downplay the risk of injury during manual of arms handling processes. Their is studied with the manipulator s refuge in mind, reduction the need for unreasonable lifting or treatment of heavy or unmanageable-to-manage materials. This is especially important in environments where workers are regularly uncovered to powders or chemicals that could pose health risks.

TOTE Systems and Regulatory Compliance

In industries like pharmaceuticals, food processing, and chemicals, maintaining submission with regulatory bodies like the FDA, USDA, and cGMP is non-negotiable. TOTE Systems plays a crucial role in serving businesses meet these rigorous standards. Their is specifically premeditated to adhere to healthful requirements, ensuring that manufacturers can confidently meet inspections and pass audits.

1. Sanitary Equipment for Strict Standards

TOTE Systems STAINLESS-steel is well-stacked with healthful design principles in mind. Their smooth surfaces and minimal joints or crevices are easy to clean, which reduces the likelihood of contamination and supports quickly cleaning cycles. This plan makes their right for industries that need to meet rigorous hygiene standards.

2. cGMP and FDA Compliance

TOTE Systems products are premeditated to meet the standards set forth by Good Manufacturing Practices(cGMP) and the FDA. Their s hygienical features control that it aligns with FDA requirements for food, drinkable, and pharmaceutical manufacturing. This ensures companies using TOTE Systems’ equipment can exert a high tear down of production timber while minimizing regulative risks.

Durability and Long-Term Value

Durability is another trademark of TOTE Systems’ equipment. Their products are made from high-quality STAINLESS nerve, ensuring long-term dependableness in even the most demanding product environments. With a focus on on durability and low-maintenance operation, businesses can swear that their TOTE Systems equipment will preserve to perform well over time, providing a strong bring back on investment funds.

By using TOTE Systems products, manufacturers can expect to tighten the associated with downtime, sustenance, and ineffectual handling SYSTEMS, allowing them to reinvest in other critical areas of their trading operations.

The TOTE Systems Advantage

What sets TOTE Systems apart from competitors is their of go through, conception, and to quality. With over 40 old age of manufacture expertness, TOTE Systems has improved a deep sympathy of the unusual needs of dry and powderise stuff treatment across a variety of sectors. Their structured solutions make it easier for manufacturers to meet the demands of high-volume production while maintaining submission with tight manufacture regulations.

TOTE Systems has well-tried itself as a trustworthy partner for businesses quest to ameliorate efficiency, heighten safety, and ensure product tone. Their extensive portfolio of STAINLESS-steel equipment and cutting-edge applied science ensures that their customers stay aggressive in fast-moving and regulated industries.

By continuously direction on conception and regulative submission, TOTE Systems clay at the cutting edge of dry and powder material treatment solutions, providing manufacturers with the tools they need to come through in an ever-evolving industry.